【NEW】MM-140A Pulsed TIG Weld checker

【MM-140A】

“Visible” welding quality management for TIG welding is recommended!

Our TIG checker is a compact and user friendly design with an encoder.

- Measurement and judgement of necessarily monitoring factors for TIG welding are possible.

Upper / Lower limits of judgement and data management of factors are possible.

Welding quality is effected by below factors.

Current : the most important factor for welding. Voltage : It can be a factor that provides voltage-noise against welding point or peripheral devices.*1 Time : important factor for welding as well as current. Shield-gas flow : it's necessary to discharge an arc stably.*2

We must measure and manage above factors.

*1: Available for touch-start welding.

*2: Our recommended flow rate sensor and input connector are connected.

welded sample

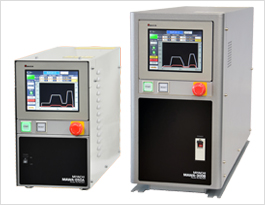

MAWA-050A/300B

Please ask for our pulsed TIG welders, too

- Measuring of long-time welding

Maximum measurement time is 9999ms, thus, it’s available for long-time pulsed TIG welding. - Able to measure even while modulation function is operated.

The modulation function is used to suppress welding faults such as blowholes.

In case of using complex waveforms control function, it enables to measure and judge each factors. - Ethernet communication

With connecting PC through LAN cable (Ethernet), uniform management is available.

The product offers one way and two way communications. In case of two way communication, reading/writing of measurement settings and data are possible. - Accessaries (Options)

- Current sensor

Two types of sensors are on line-up. The one is used for detecting max. 50A and the other one is used for detecting max. 300A. Customers need to choose suitable sensor.

RS-C300-3000/RS-C050-3000(Cable length 3m) - Torch voltage detecting cable (length 3m)

SK-1202980 - Relay cable (length 0.2m)

SK-1202967 - Flow rate sensor cable (length 3m)

SK-1202981 - Flow rate sensor

Please use our recommended product. The model is PFM510-C6-2 (SMC).

Calibration of the sensor is not done by our company, thus, customers should prepare the sensor by themselves.

- Current sensor

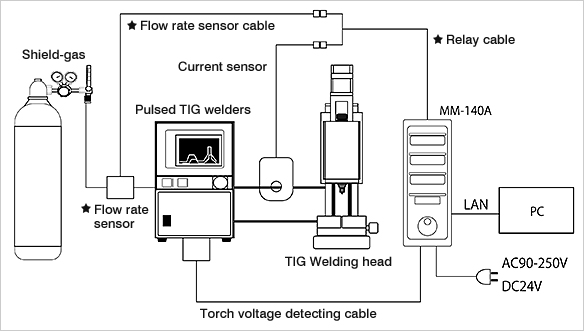

- Configuration of connecting

If flow rate sensor is not used, please note that items with ★ icons are necessary.

| MODEL | MM-140A | ||||||

| Measurement Specification | Current | Range | 01.00~50.00A / 015.0~300.0A | ||||

| Items | Peak current within all welding time / RMS current from start signal input to end signal input | ||||||

| Voltage *1 | Range | 001.0~120.0V | |||||

| Items | Peak voltage within all welding time / RMS voltage from start signal input to end signal input | ||||||

| Measurement time | Range | 0000~9999ms | |||||

| Gas flow rate | Range | 00.0~10.0(4-20mA) *2 | |||||

| Item | Average value from start signal input to end signal input (from Pre-flow to After-flow) |

||||||

| Measurement time | 00000~50000ms(±3ms) | ||||||

| Modulation frequency | Range | 0~3000Hz(reference) | |||||

| Measurement accuracy | ±2% expect for an error of sensor | ||||||

| Judgement functions | Good-bad judgement based on upper/lower limits of current, voltage, time, gas flow rate and modulation frequency / no current judgement | ||||||

| No. of schedules | 31 schedules | ||||||

| Main body specification | Power supply | Single-phase 90 to 250 V AC(50/60Hz) / 24 V DC ±10% | |||||

| Power consumption | 17W | ||||||

| External data output | Ethernet(Protocol: TCP/IP) | ||||||

| Ambient temperature / humidity during operation | Temperature 0~45℃ / humidity less than 90%(non-condensation) | ||||||

| Temperature / humidity during transport | Temperature -10~55℃ / humidity less than 90%(non-condensation) | ||||||

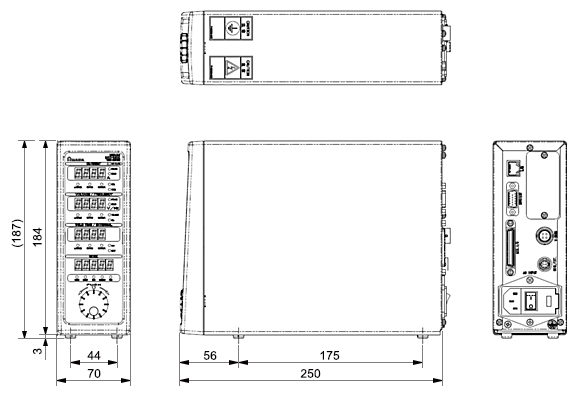

| Outer dimensions・Mass | 70(W)×250(D)×187(H)mm (Not including projections) / Approx. 2.3kg | ||||||

- *1 Measurement of voltage is available for only touch-start welding.

- *2 It depends on specification of the gas flow rate sensor.

▶ Dimensions in mm