ML-2051A.ML-2050A.ML-2150A

- Home

- Products

- Laser Welders

- YAG Laser Welder

- ML-2050A.ML-2051A.ML-2150A

◆Welding with a few heat-affected area can be done due to that laser welding is "contactless" welding.

◆Real-time Power Feedback feature ensures stable welding under optimum weld conditions.

◆Employing an optical fiber makes its automation easy.

◆Small spot size is perfect for welding of super minute parts.

◆Up to three energy sharing.

◆Controller is detachable.

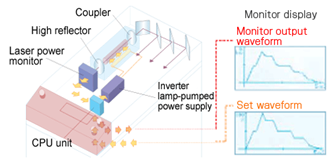

▶ Real-time Power Feedback Control

The laser output in the lamp-pumped module is monitored in real time. The monitored laser output is compared with the set waveform and power is fed back in real time, varying the energy input to the lamp to reproduce the set waveform and obtain the ideal laser output waveform.

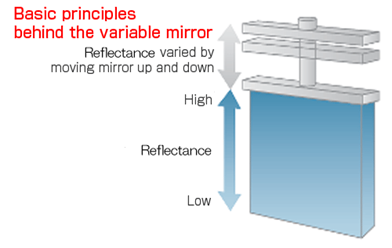

▶ Variable mirrors

These mirrors eliminate laser power loss and improve branch balance.

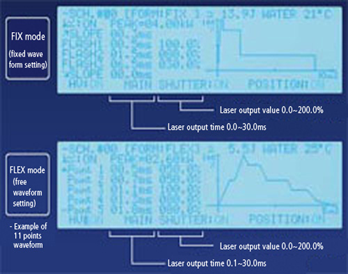

▶ Waveform control

Equipped with a "fixed mode" that features three-level waveforms, and a "flex mode" to provide more complex waveforms.

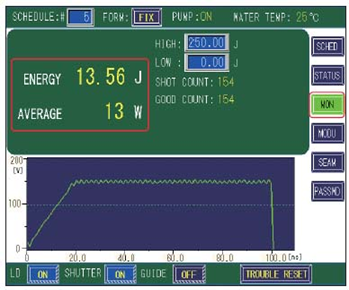

▶ Power monitor

Laser energy (J) and average power (W) are monitored to detect abnormalities.

▶ External communications

Configuration of parameters and monitoring of performance can be carried out from a separate location.

- Type: RS-485 compliant, asynchronous, full duplex

- Data speed: 9600, 19200, 38400 bps

▶ Forced Air Cooling System

The air cooling system is available. No water and piping are necessary.

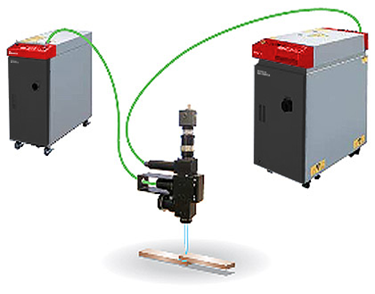

▶ Hybrid Laser Welding System

This system combines SHG green laser (ML-8150A) and the fundamental laser (ML-2000 series) at the focus unit to obtain improved welding depth and spot diameter.

▶ High-efficiency, high-quality welding

A highly power-efficient power supply has been developed that holds down high frequencies to protect the environment. Since single-phase 200/220/240 VAC ±10% is used, power supply requirements are flexible, even when this device is used overseas.

▶ Optical fiber delivery System

A maximum of three branches are possible, including energy sharing and time sharing.

▶ Improved rise speed and energy efficiency

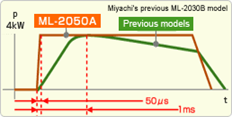

The laser output startup time has been reduced to about 1/20th of that for previous models. Also, for short-time welding under 5ms, the pulse width can be set in units of 0.02ms, five times the precision of previous models.

▶ Pulse repetition rate

A maximum repetition rate of welding and processing is 30pps.

| Model | ML-2051A | ML-2050A | ML-2150A | |

|---|---|---|---|---|

| Oscillation wavelength | 1,064nm | |||

| Maximum average power | 7W | 15W | 25W | |

| Maximum output energy | 7 J/P (Pulse width 5ms) | 15 J/P (Pulse width 5ms) | 25 J/P (Pulse width 5ms) | |

| Pulse width | Standard: 0.2 to 10.0 ms (0.1 ms steps) Fine setting: 0.20 to 5.00 ms (0.02 ms steps) |

|||

| Pulse repetition rate | 1 to 30 pps | |||

| No. of programmable schedules | 32 | |||

| Counter | Total number of outputs | 9 digits | ||

| Number of acceptable outputs | 9 digits | |||

| Fiber optic delivery | Up to 3 deliveries of laser output, including powersharing and timesharing, are available. (Option) |

|||

| External communication function | RS-485 | |||

| Power requirements | Single-phase 200 V, 220 V, 240 V AC +10%,-15%, 50/60 Hz | |||

| Cooling method | Forced air-cooled | |||

| Dimensions | 310(W) X 665(D) X 700(H) | |||

| Weight | 70kg | |||

*Specifications subject to change without notice.

▶ Dimensions in mm

.png)

.png) |

.png) |

.png) |

| Isolator | Isolator | Gimbals |

◢ Fine weld spot and deep penetration

.png) |

.png) |

| Spot dia: φ80µm | Depth: 298µm |

.png) |

.png) |

|

Spot dia: φ320µm |

Depth: 101µm |