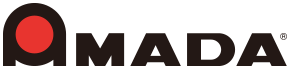

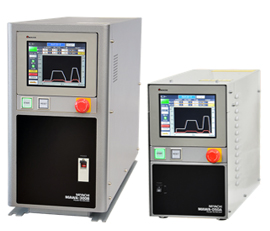

【NEW】MAWA-300B , MH-TL01A

- Home

- Products

- Fine Spot Welders

- Pulsed TIG Welder/checker

- MAWA-300B.MAWA-050A.MH-TL01A

What is MAWA-300B PULSETIG® Welding Power Supply?

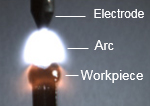

This DC type TIG welder generates arcs between an object to be welded and the tungsten electrode and carries out welding using the generated heat.

Effective for welding of precision devices and minute parts.

Individual lineup of high voltage start special purpose machines and touch start special purpose machines.

Selecting the start method appropriate for the workpiece improves the welding reliability.

Arc welding image

Precision control by constant current and short time welding

Touch start

High voltage start

▶ Features

◆ Feature of each start

- ● Touch start

- Touch electrode and work piece before start, pull up electrode, make magnetic field between electrode and work piece, generate arc

- Suppress influence of noise

Suppress causing malfunction of electrical device and breaking electrical parts with weak electrical strength near the welding point. - Secure weld on chosen point

Arc will cause from electrode touching point to electrode. This will secure place to weld. - Reduction of the running cost

Electrode life is prolonged , compared with the high voltage start, running cost can be reduced.

- ● High voltage start

- Cause arc by adding DC high voltage between electrode and work piece Position of electrode will be fixed on same place for all the time

- Non-contact

Effective in welding small parts as the arc is shot without contact. - Non-pressurized

Since electrode does not touch work piece, able to reduce distortion of work piece. - Short takt time

This method is more effective than the touch start method in reducing the takt time because it is not necessary to vertically move the torch.

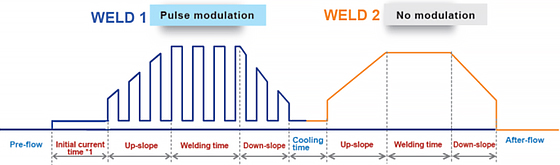

◆ Pulse modulation feature

Inner blow halls generated at welding are reduced due to this feature which inputs heat intermittently.

Size and shape of arc ball is controllable.

◆ Envelope feature

The upper and lower limit of criterial current waveform are set to judge welding quality.

Touch start feature

Inner blow halls generated at welding are reduced due to this feature which inputs heat intermittently.

Size and shape of arc ball is controllable.

◆ Envelope feature

The upper and lower limit of criterial current waveform are set to judge welding quality.

Touch start feature

* ON/OFF of pulse modulation can be set to each Up Slope /WELD /Down slope of WELD1 and WELD2.

*1:Only the touch start functions.

TOUCH START HEAD MH-TL01A

- Weld head that can be easily connected to the MAWA-050A (a model dedicated for touch start)!

- The torch is motor driven exclusively for the MAWA-050A (a model dedicated for touch start).

- The dedicated controller easily sets the electrode position and speed.

- Torch floating lock feature

The MH-TL01A keeps a certain torch hoist amount even if the workpiece height varies.

This realizes a stable penetration amount.

| Model name | MAWA-300B-00-00 | MAWA-300B-00-01 | ||

| Start method | Touch start | High voltage start | ||

| Power supply voltage | Three-phase 200V AC ±10% (50/60 Hz) |

|||

| Power consumption | 13.2kVA | |||

| Maximum output current | 300A | |||

| Control method | Secondary constant current control Inverter type (Control frequency: approx. 45 kHz) |

|||

| Maximum no-load voltage | DC95V | |||

| Rated load voltage | 22 V (300-A power ON status) | |||

| Duty cycle (*1) | 5%(300A), 10%(210A), 20%(150A), 30%(122A), 40%(97A), 50%(80A), The maximum duty cycle for weld time 1 sec. is 50% (80 A or less). |

|||

| Number of conditions (SCHEDULE) | 127 conditions | |||

| Time setting range | Pre-flow | 0~9999 ms (in unit of 1 ms) | ||

| Initial current | 0~999 ms (in unit of 1 ms) | |||

| WELD1 (*2) |

Up slope | 0~99.9 ms (in units of 0.1 ms) 100~999 ms (in unit of 1 ms) |

||

| Main welding | ||||

| Down slope | ||||

| Cooling (*2) | 0~1000 ms (in unit of 1ms) | |||

| WELD2 (*2) |

Up slope | 0~99.9 ms (in units of 0.1 ms) 100~999 ms (in unit of 1 ms) |

||

| Main welding | ||||

| Down slope | ||||

| After flow | 0~9999 ms (in unit of 1 ms) | |||

| Current setting range | Initial current WELD1 WELD2 |

Settable in the range of 15 to 300 A (in unit of 1 A) (Welding current, peak current, base current) |

||

| Installing conditions | Ambient temperature: +5~+40℃ | |||

| Maximum humidity: 85% or less (without condensation) | ||||

| External dimensions | 408 (H) mm × 210 (W) mm × 603 (D) mm (excluding projections) | |||

| 408 (H) mm × 210 (W) mm × 705 (D) mm (including the cable gland of the terminal cover) |

||||

| Mass | Approx. 45 kg | |||

| CE | Correspond | |||

| CCC | ||||

- *1: The duty cycle (load time for a period of 10 minutes) of “JIS C9300-1 3.37” is not adopted.

- *2: WELD1 + Cooling +WELD 2 ≦ 4000 ms

| Model name | MH-TL01A‐00‐01 | |

| Follow-Up Mechanism Type | For PULSETIG welding touch start | |

| Power Supply Voltage | 100–240 V AC ±10%, 50/60 Hz, 70 VA | |

| Stroke | 50 mm max. | |

| Electrode-Lifting-Up Amount | 0.1 to 9.9 mm (in units of 0.1 mm) | |

| Electrode Force | 0.6 N (60 g) min *1 | |

| I/O | SUMICON (34pins) | |

| Number of Welding Schedules | 15 Schedules (selectable externally) | |

| Operating Conditions | Temperature: 5 – 40°C | |

| Humidity: 85% or less (No condensation) | ||

| External dimensions | Body | 120(W)mm × 414(D)mm × 460(H)mm |

| Controller | 70(W)mm × 250(D)mm × 185(H)mm | |

| Mass | Body | Approx. 8 kg |

| Controller | Approx. 3 kg | |

- *1: The electrode-lifting-up amount increases or decreases according to the head descending speed when the electrode makes contact with the workpiece.

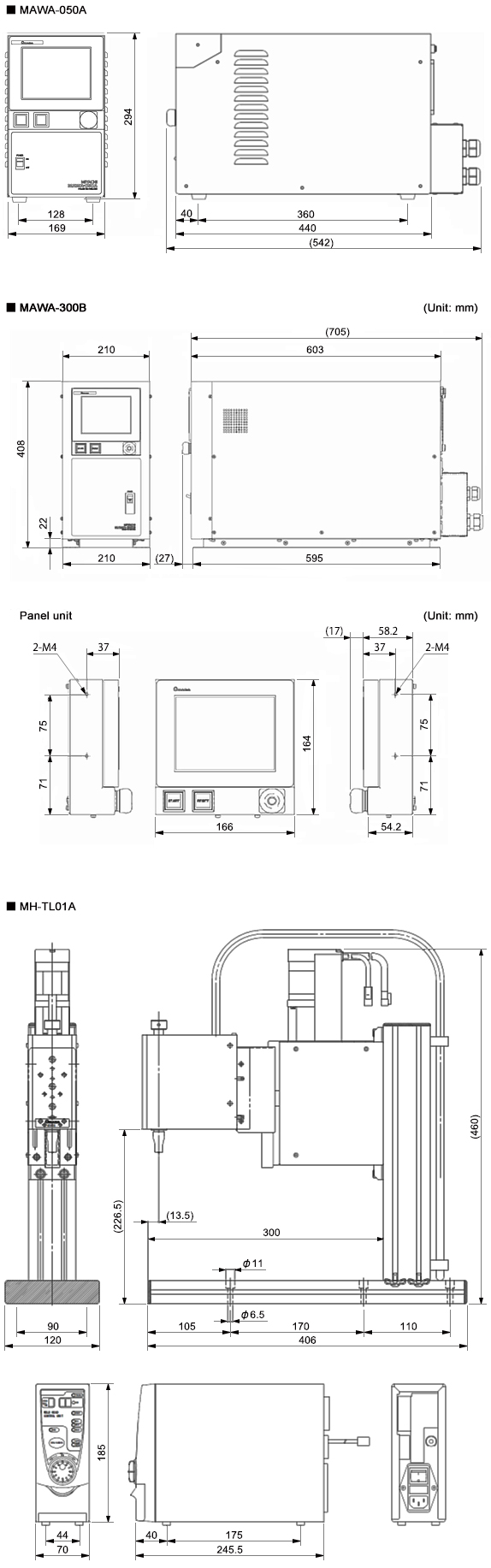

▶ Dimensions in mm